SUMMARY

Crypto mining has become highly competitive, with many users entering the industry. Almost every modern user has specialized mining hardware like an ASIC miner with advanced features to beat the competition in the mining network and enhance their chances of earning mining rewards.

Though ASIC miners are ideal for crypto mining in this competitive market, one potential drawback is that they generate a significant amount of heat. If not treated properly, those high temperatures can cause damage to your mining set up or may even pose fire hazards. Hence, miners often install immersion cooling systems to dissipate heat and maintain optimal temperature.

Miners prefer immersion cooling systems for their efficient heat dissipation, quieter nature, and more reliable alternative option. If you’re relatively new to the industry and interested in knowing more about immersion cooling systems for ASIC miners, this blog is exclusively for you.

Immersion Cooling Explained

Immersion cooling is a liquid cooling technique in which ASIC miners are fully submerged in a non-conductive, dielectric fluid. The surrounding liquid absorbs the heat generated by the ASIC components.

The temperature gradient in the liquid makes the warmer and less dense liquid rise to the surface. This heated fluid is then removed and replaced by cooler liquid from the bottom, a process known as natural convection. Since this method relies on passive heat transfer, it eliminates the need for active cooling components like fans, significantly enhancing the energy efficiency of your ASIC miner.

Many modern miners prefer immersion cooling as they need not deal with dust, heat spots, and loud noise. They prefer immersion cooling for its efficient cooling, even temperature distribution, and reduced noise.

Unlike air or fan cooling, which can struggle with dust, heat spots, and noise, immersion cooling ensures even temperature distribution, minimal maintenance, and reduced noise.

There are two types of immersion cooling, namely

1. Single-Phase Immersion Cooling

In a single-phase liquid cooling system, server racks are placed directly into a special non-conductive liquid that stays in liquid form the whole time. As the servers heat up, that heat is absorbed by the surrounding liquid. The warm liquid is then sent to a cooling tower through a cooling distribution unit, where it’s cooled down before being cycled back into the tank.

The entire setup is pretty straightforward compared to more complex two-phase systems. It’s easier to manage and inexpensive to install, but it’s not quite as efficient and usually uses more energy to keep things cool.

Here are some examples of single-phase immersion cooling systems:

- Fog Hashing Immersion Cooling C1: A compact, plug-and-play option that’s simple to set up.

- Fog Hashing Immersion Cooling C2: Ideal for home mining with quiet and efficient performance.

- Fog Hashing Immersion Cooling C6: A larger unit built to handle multiple miners at once.

- Fog Hashing Immersion Cooling Suit B100: A powerful system that can manage heavy loads up to 100 kW.

2. Two-Phase Immersion Cooling

In a two-phase cooling system, servers are housed in a sealed tank filled with a special liquid that has a low boiling point. As the servers generate heat, the liquid starts to boil, turning into vapor. Unlike single-phase systems, where the liquid stays in one state, this method uses the phase change, from liquid to vapor, to carry heat away from the ASIC components.

The vapor rises and moves through a cooling system located above the servers, where it condenses back into liquid form and drips back into the tank to start the cycle again.

While two-phase systems cost more to set up than single-phase ones, they’re more efficient and take up less space overall.

Components of Immersion Cooling

While single-phase and two-phase immersion cooling systems differ in operation, they share several key similarities, especially in the core components they rely on.

1. Dielectric Fluids

Choosing the right dielectric fluid is crucial for liquid cooling systems. The fluid needs to have strong heat-transfer capabilities, be non-conductive to avoid electrical shorts, and remain chemically stable over time for long-lasting performance. Common options include synthetic oils and specially designed cooling fluids.

2. Cooling Tanks

In any immersion cooling setup, these tanks are essential for housing both the dielectric fluid and the IT hardware, such as ASIC miners or server racks. They must be robust, leak-proof, and designed to safely support the weight and layout of the equipment while allowing for proper fluid circulation.

In addition, the tanks should be easy to access and maintain, with features that support regular monitoring, servicing, and fluid replacement. Because off-the-shelf options often don’t meet the specific demands of each facility, many miners often design and build custom cooling tanks tailored to their infrastructure, ensuring maximum efficiency, safety, and scalability.

3. Enclosure Design

The design of the immersion cooling enclosure plays a vital role in efficient heat dissipation. It must ensure maximum exposure of the ASIC components to the dielectric fluid while maintaining a safe, stable, and well-regulated environment. To meet the unique requirements of different mining setups, manufacturers often tailor these enclosures to suit specific hardware configurations and performance goals.

4. Heat Exchangers

When ASICs operate, they generate a significant amount of heat, which is absorbed by the surrounding dielectric fluid. To prevent the fluid from reaching temperatures that could compromise cooling efficiency or hardware performance, a reliable heat removal system is essential, and that’s where heat exchangers come in.

Heat exchangers work by transferring the absorbed heat from the dielectric fluid to an external cooling loop, such as a water or air-based system. They’re typically compact, efficient, and can be seamlessly integrated into the design of immersion cooling tanks.

By maintaining a stable fluid temperature, heat exchangers play a key role in sustaining optimal operating conditions and extending the lifespan of both the fluid and the ASIC components.

5. Pump and Filtration Systems

A critical component of any immersion cooling setup is the pump system, which ensures continuous and efficient circulation of the dielectric fluid. These pumps move the heated fluid from the immersion tank to the heat exchangers, where the excess heat is removed, and then return the cooled fluid to the tank.

Additionally, filtration systems are often integrated to maintain the purity and performance of the dielectric fluid. Over time, dust, particles, or residues from the hardware can accumulate in the fluid, potentially affecting its thermal conductivity and chemical stability. Filtration units help remove these contaminants, extending the life of the fluid and ensuring optimal heat transfer.

How Immersion Cooling Differs from Traditional Cooling Methods?

ASIC miners carry out intense computational tasks that produce a substantial amount of heat. Managing this heat effectively is essential, as excessive temperatures can trigger thermal throttling, automatically reducing the miner’s performance to avoid overheating. Over time, continued exposure to high heat levels can accelerate hardware wear and tear, increasing the risk of malfunctions and reducing the miner’s overall lifespan.

Conventional cooling methods like air and liquid cooling have been used to address the heat generated by ASIC miners. Air cooling, the most widely used technique, employs fans to move air around the miners and disperse heat into the surrounding environment.

Although it’s affordable and easy to implement, air cooling becomes less effective in tightly packed mining operations or hot climates. Additionally, its dependence on airflow can lead to dust buildup, which reduces cooling efficiency and increases the need for frequent maintenance.

Liquid cooling, in contrast, uses a circulating coolant to absorb heat from ASIC miner components and transfer it to a radiator, where the heat is then released. Although it offers greater efficiency than air cooling, traditional liquid cooling systems are more complex, relying on pumps, tubing, and radiators. This complexity raises the risk of leaks and hardware malfunctions, while also making large-scale deployment more challenging due to the elaborate setup and significant space demands.

Although both traditional cooling methods offer some level of effectiveness, they fall short in efficiently handling the intense heat produced by ASIC miners. These limitations highlight the growing need for advanced solutions such as immersion cooling, which can significantly improve the performance, reliability, and scalability of cryptocurrency mining operations.

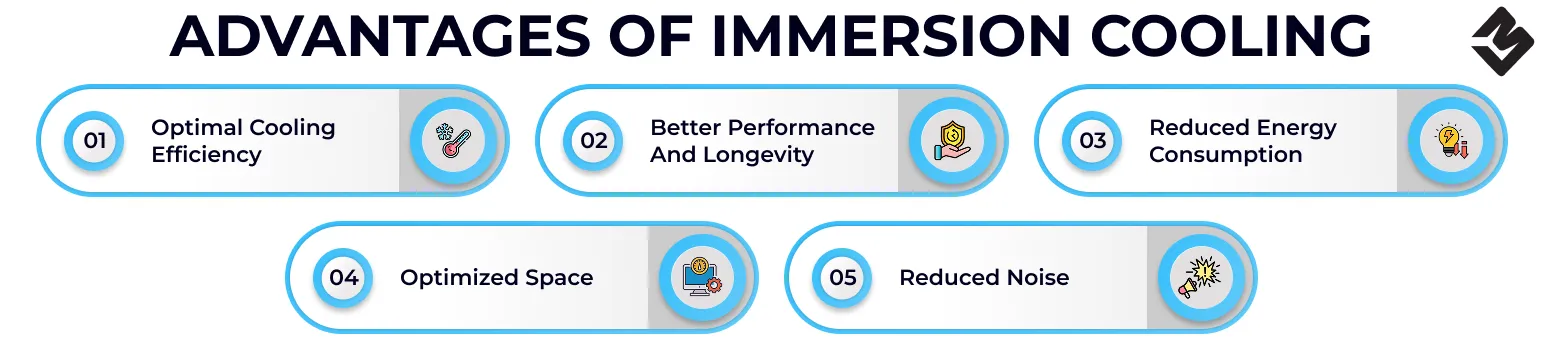

Advantages of Immersion Cooling

Immersion cooling provides a lot of benefits that overcome the limitations of traditional cooling methods in cryptocurrency mining. It not only boosts the operational efficiency of mining rigs but also extends their lifespan and improves overall performance.

1. Optimal Cooling Efficiency

Conventional air and liquid cooling systems frequently fall short when it comes to managing the extreme heat output produced by high-performance ASIC miners. These systems often lead to inconsistent temperature control, increased energy consumption, and the risk of thermal throttling, which can degrade performance and hardware lifespan.

On the other hand, immersion cooling offers a highly effective alternative by fully submerging the mining hardware in a thermally conductive, dielectric fluid. This method allows for rapid, uniform heat transfer away from critical components, dramatically improving cooling efficiency and maintaining optimal operating temperatures, even under heavy workloads.

2. Better Performance and Longevity

Immersion cooling systems offer exceptional thermal management, keeping ASIC miners consistently within optimal temperature ranges. By preventing overheating, these systems effectively avoid thermal throttling, a common issue that can severely limit processing power under traditional cooling methods. As a result, ASIC miners are able to operate at optimal performance for longer durations without interruptions.

Furthermore, by minimizing temperature fluctuations and reducing the overall thermal stress on sensitive electronic components, immersion cooling helps to extend the lifespan of the mining hardware significantly. This reduction in heat-related wear and tear means fewer failures, lower maintenance costs, and a greater return on investment over time.

3. Reduced Energy Consumption

Immersion cooling systems drastically reduce the energy demands associated with traditional cooling methods, such as high-powered fans and industrial-scale air conditioning units.

In conventional setups, these components consume a substantial portion of the total energy used in a mining operation, contributing to increased operational costs and reduced energy efficiency.

Immersion cooling, on the other hand, utilizes a direct-contact approach, where mining hardware is submerged in a specially designed, thermally conductive dielectric fluid. This allows for efficient and immediate heat absorption and dissipation without relying on air circulation or refrigeration.

In short, immersion cooling minimizes energy waste and significantly cuts down on the electricity costs. Thus, making it a far more sustainable and cost-effective solution for large-scale crypto mining operations.

4. Optimized Space

One of the key advantages of immersion cooling is its ability to support high-density hardware configurations without compromising thermal management. Traditional air and liquid cooling systems require sufficient spacing between devices to allow for proper airflow and heat dissipation, often limiting how many miners can be housed within a given area.

In contrast, immersion cooling submerges the equipment directly into a thermally conductive, dielectric fluid that provides consistent and uniform heat removal from all surfaces of the hardware.

The superior cooling capability eliminates the need for wide spacing and bulky ventilation infrastructure, allowing miners to be installed much closer together. The result is a significantly more compact and efficient layout, which is especially beneficial in environments where real estate is limited or expensive.

The space-saving design not only maximizes the use of available physical infrastructure but also increases overall mining capacity per square foot, enhancing the operational scalability and profitability of mining facilities.

5. Reduced Noise

One of the often-overlooked challenges in traditional air-cooled mining operations is the significant noise generated by high-speed fans and industrial cooling systems. These fans work continuously to dissipate the intense heat produced by ASIC miners, resulting in noise levels that can be extremely noisy, particularly in residential areas, shared buildings, or other noise-sensitive environments.

Noise pollution can lead to discomfort and even restrictions on where mining setups can be located. Immersion cooling effectively eliminates this issue by removing the need for air circulation and fan-based cooling altogether. Since the hardware is submerged in a non-conductive fluid that passively and efficiently dissipates heat, there’s no need for noisy mechanical components.

The result is near-silent operation, creating a much more pleasant and unobtrusive working environment. It makes immersion cooling appealing for miners operating in all locations where noise control is a top priority, and it further contributes to a cleaner, more sustainable, and user-friendly mining infrastructure.

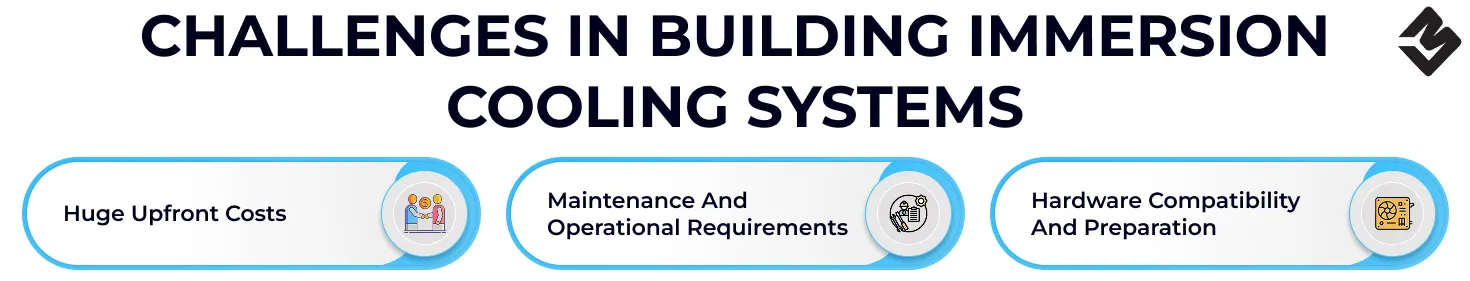

Potential Challenges in Building Immersion Cooling Systems

Although immersion cooling provides a wide range of advantages for cryptocurrency mining operations, it’s essential to recognize the challenges and considerations involved in adopting this technology. Being aware of these potential obstacles is vital for miners evaluating whether a shift to immersion cooling is the right move for their setup.

1. Huge Upfront Costs

One of the main challenges in transitioning to immersion cooling is the substantial upfront investment it requires. Compared to traditional air or liquid cooling solutions, the costs associated with immersion systems are notably higher.

For instance, expenses include purchasing specialized immersion tanks, dielectric cooling fluids, heat exchangers, and making any necessary infrastructure modifications to support the new system.

Conducting a comprehensive cost-benefit analysis is critical before implementing the immersion cooling system for your ASICs. This analysis should compare the initial capital required with the potential long-term advantages, such as enhanced energy efficiency, lower power consumption, and increased hardware longevity.

Additionally, operators should consider enhancing savings from decreased maintenance needs and reduced ongoing operational costs, which can help recover the initial investment over time.

2. Maintenance and Operational Requirements

Although immersion cooling systems typically demand less maintenance than conventional cooling methods, they are not completely maintenance-free. Regular monitoring and routine maintenance are essential to ensure consistent and efficient system performance.

It includes checking the condition and level of the cooling fluid, inspecting pumps and heat exchangers to confirm they’re functioning properly, and verifying whether the filtration system is effectively removing any particles or contaminants from the liquid.

Additionally, operators must also be aware of the unique operational requirements that come with immersion cooling. These include managing the lifecycle of the cooling fluid, such as replacement schedules, degradation monitoring, and understanding the correct procedures for safely adding or removing hardware from the immersion tanks.

Proper handling and maintenance practices are key to maximizing the benefits and longevity of an immersion cooling setup.

3. Hardware Compatibility and Preparation

Before implementing immersion cooling, it’s critical to understand that not all ASIC miners are designed to be submerged. Many models require specific modifications to function safely and effectively in an immersion environment. The first and most common step is removing the built-in cooling fans, which are unnecessary.

Beyond fan removal, certain components may need additional sealing or protective measures to prevent fluid intrusion. For example, connectors, exposed circuitry, or thermal sensors may be vulnerable to even dielectric fluids if not properly insulated or shielded.

Improper preparation can have serious consequences. Even though dielectric fluids are non-conductive, prolonged exposure to contaminated or poorly maintained fluids can lead to corrosion, short circuits, or degradation of sensitive parts like capacitors and solder joints.

Best Practices for Immersion Cooling Systems

Adopting immersion cooling can greatly improve the efficiency and durability of ASIC miners, but maximizing its benefits requires following the best practices. Below are some essential guidelines that miners can follow to ensure optimal performance and reliability.

1. Selecting the Right Coolant

When setting up an immersion cooling system, it’s crucial to choose a coolant that aligns with both performance and sustainability. opt for specialized immersion cooling fluids that are non-conductive to prevent electrical hazards and eco-friendly to minimize environmental impact.

Choose coolants that are engineered to ensure safe operation, efficient heat transfer, and compliance with sustainability standards. Thus, you can expect long-term performance and responsible system maintenance.

2. Auditing ASICs Regularly

Performing consistent and thorough inspections of your immersion cooling system is crucial for maintaining optimal performance and preventing costly failures. These routine checks help identify early signs of wear, malfunction, or inefficiencies, such as fluid degradation, pump irregularities, or heat exchanger buildup, before they develop into more serious problems.

Key areas to inspect include fluid levels and clarity, pump and filter function, temperature consistency, and the integrity of seals and connections. By proactively monitoring the system, operators can address minor issues promptly, reduce downtime, and extend both the effectiveness of the cooling setup and the operational life of the ASIC hardware.

3. Emergency Responsiveness

It’s essential to have a well-defined emergency response plan in place to quickly and effectively address unexpected incidents such as fluid spills, leaks, or system malfunctions. These events, if not handled promptly, can lead to equipment damage, extended downtime, and increased operational costs.

A comprehensive preparedness strategy should include clearly documented procedures for isolating and shutting down affected components, safely containing and cleaning up fluid spills, and repairing or replacing faulty parts.

Additionally, ensure that staff are properly trained in emergency protocols and that necessary safety equipment, such as absorbent materials, spill kits, and protective gear, is readily accessible. Regular drills and system audits can further strengthen your ability to respond quickly, minimizing disruption and protecting both your hardware and Personal.

CONCLUSION

Immersion cooling offers a powerful and efficient way to enhance the performance and lifespan of your ASIC miner while reducing noise and managing heat more effectively than traditional cooling methods. For beginners, understanding the basics, from choosing the right coolant and tank setup to ensuring proper maintenance, is key to building a reliable and sustainable system.

With the increasing popularity of crypto mining, immersion cooling is one potential solution that not only maximizes hardware efficiency but also supports eco-conscious practices. By starting with the right knowledge and tools, you can optimize your mining operations and enhance your mining success.

Check out the latest ASIC Miners

FAQs ON IMMERSION COOLING

-

Is immersion cooling safe for ASIC miners?

Yes, as long as you use the correct dielectric fluid and follow proper setup and maintenance procedures. These fluids are specifically designed not to conduct electricity and are safe for use with sensitive electronic components.

-

Does immersion cooling really increase the lifespan of ASIC miners?

Yes. By maintaining stable and lower operating temperatures, immersion cooling reduces thermal stress on components, which helps prevent premature hardware failure and extends the life of your mining equipment.

-

Is immersion cooling noisy?

No. One of the major advantages of immersion cooling is that it drastically reduces noise by eliminating the need for high-speed fans and large Heating, Ventilation, and Air Conditioning (HVAC) systems.

-

How often do I need to replace the cooling fluid?

The dielectric fluid can last several years with proper filtration and maintenance. However, it’s important to monitor fluid quality regularly and replace it if contamination or performance degradation occurs.

Han su

Han Su is a technical analyst at CryptoMinerBros, a leading provider of cryptocurrency mining hardware. He has over 5 years of experience in the cryptocurrency industry and is an expert in mining hardware, software, and profitability analysis.

Han is responsible for the technical analysis and research on ASIC Mining at Crypto Miner Bros. He also writes in-depth blogs on ASIC mining and cryptocurrency mining, and he has a deep understanding of the technology. His blogs are informative and engaging, and they have helped thousands of people learn about cryptocurrency mining.

He is always looking for new ways to educate people about cryptocurrency, and he is excited to see how the technology continues to develop in the years to come.

In spare time, Han enjoys hiking, camping, and spending time with his family. He is also an avid reader, and he loves to learn about new things.